The Inoxsu Pipe Repairing System offers an extensive range of pipe damage control above & below ground including systems under pressure. Inoxsu clamp’s light-weight wrap-around pipe repair clamps are available to casing widths to contain pin-holes, cracks, corrosion blisters, and large hole damage

Inoxsu has 15-years experience worldwide proving itself as an increasingly popular alternative to traditional pipe joining, such as butt welding, flanging, grooving, or threading pipe ends.

Enhance safety in water, natural gas, and oil pipelines with the repair clamps we produce.

Redefine global standards with the easy repair clamps we produce for pipelines.

At Inoxsu, we are turning our vision of making a global impact into reality by exporting repair clamps to 21 different countries. With our products, we offer top quality solutions suitable for diverse climates and working conditions across a wide geographical area.

Our products are manufactured to withstand high pressures, allowing you to safely repair your pipelines in emergency situations. This helps prevent leaks and malfunctions, ensuring your systems have a longer lifespan.

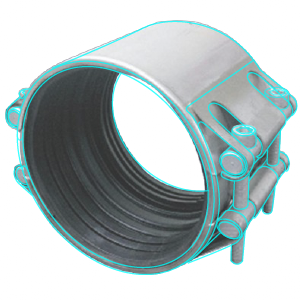

Used for repairs caused by holes and impacts in water, natural gas, and oil pipeline pipes.

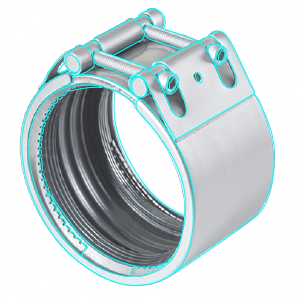

Used for repairs caused by cracks, holes, and impacts in drinking water and oil pipeline pipes.

Manufactured for use in extra outlets from your drinking water and oil pipeline pipes.

Manufactured for use in extra outlets from your drinking water and oil pipeline pipes.

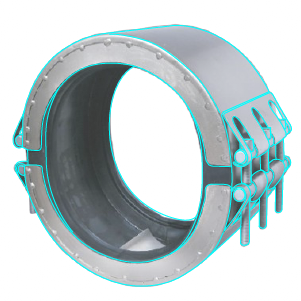

Ensures leak-proofing in water, natural gas, and oil pipes by encasing the coupling without breaking it.

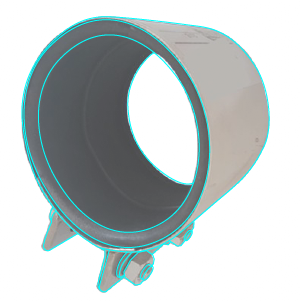

In HDPE pipes, it provides a seal by gripping the body with its claws to prevent slipping after repair.

Used at the junction of two pipes with the same or different diameters. Manufactured from St 37 steel.

Featuring a stainless steel body and rubber interior, it ensures a leak-proof seal with stainless nuts and bolts.

At Inoxsu, our working process consists of four main steps: measurement determination, custom production, installation, and quality testing. During our production process, each repair clamp undergoes rigorous quality control to ensure it meets all international certification requirements.

After the necessary measurements are taken for the damaged area, they are communicated to our production team.

Our repair clamps are manufactured to fit the required pipe type, diameter, and specific damage type.

After production phase, our easy repair clamps are installed directly over the damaged area on the pipeline.

In the final step, necessary pressure and leak tests are conducted to complete the repair process.